PRODUCTS

Milling

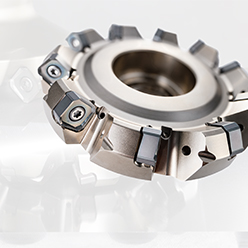

- MB45

- Versatile to general purpose, high performance, high quality, and long tool life solution. Achieves both positive "low resistance" and negative "fracture resistance" at a high level. Provides a beautifully finished surface.

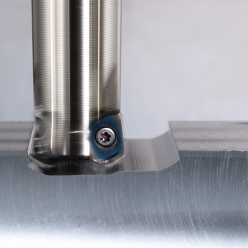

- MA90

- Unique tangential end mill solves problems in machining. New grade PR18 Series and unique insert cutting-edge design create high-quality machining with longer tool life. Providing a beautiful surface finish with excellent wall accuracy.

- MFH Boost

- High feed plus large D.O.C. for greater milling capabilities

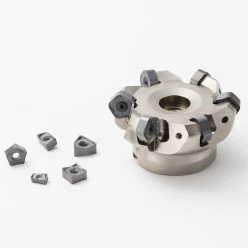

- MEV

- High Performance Milling. Newly Developed Triangular Inserts for Provide Low Cutting Forces and Increased Rigidity.

- MFSE45

- Rough and Finish in 1 Pass with Excellent Surface Finish

- MFWN Mini

- Excellent Performance and Durability in a Smaller, Economical Size

- MFF

- Innovative finishing technology with increased efficiency. High-quality surface finish

- MFLN

- Tough 4-edge Vertical Inserts Provide High Reliability on Heavy Milling at Large Depths of Cut and High Feed Rates.

- MECHT

- Helical End Mill for Titanium Alloy Machining. Unique Design for Stable Titanium Alloy Milling.

- PR015S

- Insert Grade for Machining Hardened Material. Provides Long Tool Life and Stable Machining in Hardened Material.

- MEAS

- Excellent Scatter Prevention to Ensure Stable. High Speed and High Efficiency Machining for Aluminum. AM Chipbreaker with Tough Edge was Added to the Lineup.

- MFH Series

- High Efficiency and High Feed Cutter. Cutting Diameters Starting at ø8mm. GH Chipbreaker with convex Cutting Edge Design Reduces Chatter and PR015S added to Lineup .

- MFSN88

- Economical Inserts with 8 Cutting Edges. Reduces Cost in Shoulder Roughing

- MFPN66

- Economical Inserts with 10 Cutting Edges. Reduces Chattering with Low Cutting Force Design

- TN620M

- New cermet for milling. High quality surface finishing in milling process

- MFAH

- High efficiency finishing cutter for aluminum machining.

Low cutting force and reduce burrs.

Improve the productivity.

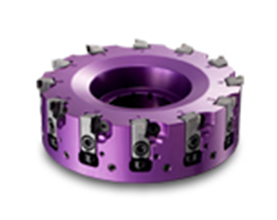

- MFK

- High-efficiency, multi-edge cast iron machining cutter. Surpress the chatter and excellent sharpness with Negative insert

- MFH

- High efficiency and high feed cutter. High feed cutter corresponding to the various machining by three chipbreakers. Surpress the chatter with a three-dimensional convex cutting edge

- MFH Micro

- Extra small diameter high feed cutter. Line up from diameter 8mm. Low cutting force design realizes high efficiency machining.

- MEW

- New generation 90° end mill with double-sided 4-edge insert. Reduce cutting force equivalent to positive inserts with KYOCERA's unique mold technology.

- MFWN

- Double-sided 6-edge insert 90° cutter. Reduce cutting force and chattering. Fracture resistance with excellent thick edge design

- MFPN

- Double-sided 10-edge insert 45° cutter. Low resistance in the helical cutting edge structure. Fractures reduced by the double-edge construction.

- MRX

- Low cutting force radius cutter. Achieve high efficiency machining and low cutting force by helical cutting-edge insert design

- MRW

- High-efficiency radius cutter with multiple edges. Economical double-sided 8-edge insert. Low cutting force due to helical cutting-edge insert design

- PR1535 / CA6535

- Milling grade heat resistant alloy and difficult-to-cut materials. Two grades cover wide range of work material and machining

- Modular End Mill

- Simple indexable threading tool. Achieve high-quality, long tool life and economical efficiency by high precision mold technology

- MSRS90

- Heavy cutting cutter. MSRS90 distribute the resistance at the beginning cutting with a dedicated high performance nicked insert

- MSR

- Heavy cutting for face mill MSRS15 cutter. Depth corresponding notch MSR type. Achieve high efficiency machining in heavy cutting

- MEC

- Positive 90° cutter. General purpose cutter. Heavy cutting for MECH cutter can be as low resistance machining by nicked insert

- MST

- Slot mill. Three types full coverage range from 1.6mm to 23.3mm

- HS-MFAL

- High feed cutter for aluminum machining. Light weight aluminum body, compact cartridge adopted, and high reliability at the time of high-speed rotation