PRODUCTS

Solid Tools

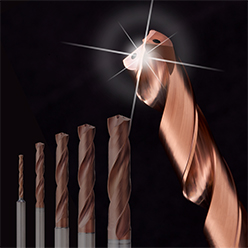

- KDA Mini

- A small diameter drill with a machining diameter from ø1.0 to ø2.9, achieved High Precision, Long Tool Life, and Stable Machining. Solve drilling problems with a wide line-up that supports up to 8D.

- KDZ

- New Flat Bottom Drills with Unique Coating Technology Provides Long Tool Life, High Precision and Stable Machining

- 2KMB

- Solid tool for hardened material supporting up to 70 HRC is now available! New PVD coating provides long tool life, high quality and stable machining in various hardened materials

- KDA

- Striking the Perfect balance between Performance and Cost. Highly Efficient and Cost Effective. New Universal Solid Carbide Drill is Now Available.

- 2ZDK-HP

- New generation flat bottom drill. Stable machining in a wide range of applications including counterboring and drilling in cylinder Surfaces.

- 4MFK / 4MFR

- Good for High Feed Machining of Steel. High Efficiency with Unique Variable Helix Design

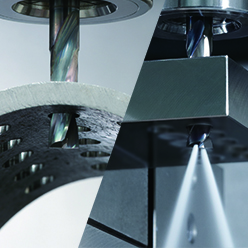

- Micro Industry Tools

- Since 1987, Kyocera has designed and manufactured tight tolerance carbide cutting tools and miniature parts for a broad range of markets including the electronics, industrial, medical and aerospace industries.

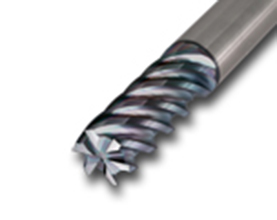

- 4/5/6RFH

- High efficiency roughing endmill for difficult-to-cut material (with coolant hole).

Multi-edge design improve productivity.

- 3AFK

- High efficiency and excellent precision machining with 3-flutes.

- 4JER

- High productivity and stability in Heat Resistant Alloy machining.

- 4TFK / 4TFR

- Achieve high efficiency machining with high feed rate by improving chip evacuation for difficult-to-cut materials

- 6PFK / 8PFK

- High-efficiency multi-blade end mill. High feed of shoulder machining with 6 blades / 8 blades achieve high efficiency machining

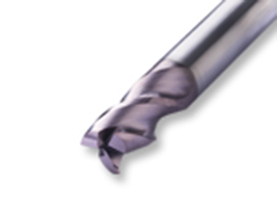

- 2SEB

- High efficiency ball nose end mill. Good sharpness with a special tip shape. Stable chip evacuation in large flute

- 3ZFK

- 3-dimensional high efficiency end mill. 3-blade specifications for plunging, slotting, and corresponds to the finishing